Tank calibration services help you measure and verify quantities and volume in large petroleum, fuel and chemical storage tanks. Calibration is the method by which the exact volume of your tank is calculated in line with specified measurement standards. This process is key to obtaining accurate measurements of quantity and keeping good contractual relationships with your clients, governing bodies and insurance companies.

Calibrations are all carried out and certified to appropriate international standards. Calibration is by process, which may be by varying methods such as EODR method, 3d Scanning and Strapping depending on type/design/siting and preferences. The tank calibration shall be included with Shell settlement including plumbness, roundness and volumetric calibration

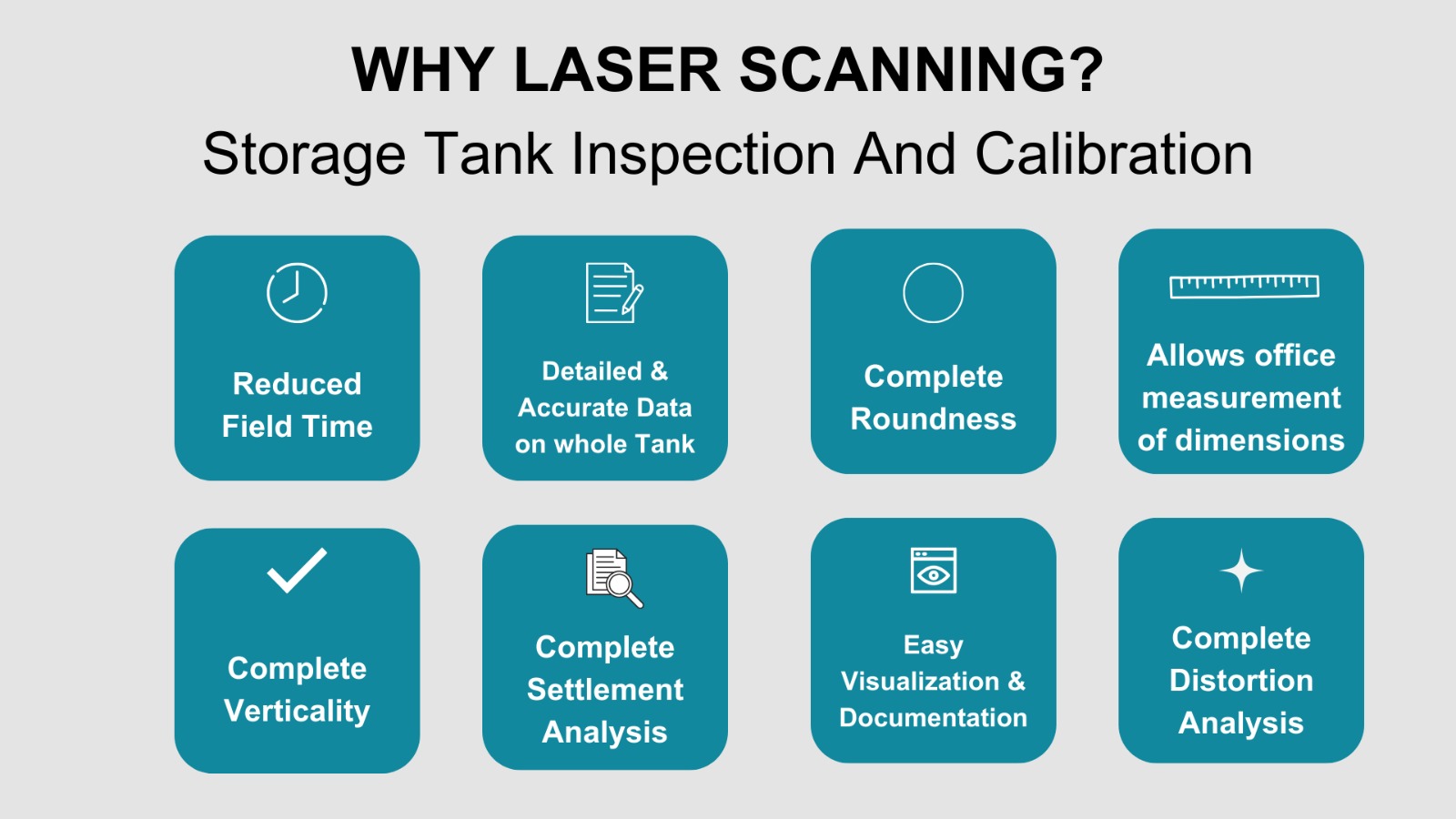

Clients have a requirement for an efficient tank calibration service that is able to provide accurate calibration tables and survey reports whilst causing minimal onsite impact in order to reduce disruption to operations. The availability of both the latest technology and the safest calibration methodologies is of primary concern to clients when selecting a total quality assurance partner.

Tank Calibration is completed to API standards, ISO standards or client specified standard and includes the following:

The latest issued revision or edition of following standards, especially API MPMS (Manual of Petroleum Measurement Standards), were used in the preparation of these guidelines,

In EODR method, circumferential target points on the tank shell wall, for any given course, are mathematically and statistically analyzed almost instantaneously to give the required course diameter. The calibration can be accomplished from the ground level. Laser ranging and optic-encoding methods are applied to determine the measurements, at each 10 mm vertical distance and at each 10° circumferentially, on the tank shell. Based on this coordinate computation, the space model of vertical tank is being established. Regarded as cylinder, the volume of tank can be calculated by using fitted radius of each course. Weighted Average Method and Direct Iterative Method were used to carry out radius fitting.

Trimble S5 Ti-M Monitoring Total Station: It detects targets without interference from surrounding prisms, ensuring target lock over long distances. The Trimble 4D control Software makes it easy to set real time notifications when structural or environmental movements occur, resulting in timely safety decisions.

3D Laser scanning technology empowers to rapidly perform comprehensive and detailed measurement and analysis. Unlike traditional techniques, it can capture the entire equipment structure in detail within the span of a few hours, minimizing scheduled downtime. The unprecedented measurement coverage provides high-resolution point-cloud data to the user and enables further analysis to be conducted. Scans can be captured safely from the ground without interfering with on-site activities. For large scale storage tanks and barges, 3D laser scanners capture accurate position information that can be used to identify true shape, geometry, deformation, and locations of interior structures.

Whether you’re doing a topographic survey, capturing as-builts, performing comprehensive data analysis, new construction or a renovation model, Trimble solutions empower quick and accurate scanning, registration and creation of comprehensive deliverables.

Our scanners have you covered with:

Trimble’s advanced software and scanning solutions give you the power to quickly capture, analyze, model, and deliver: